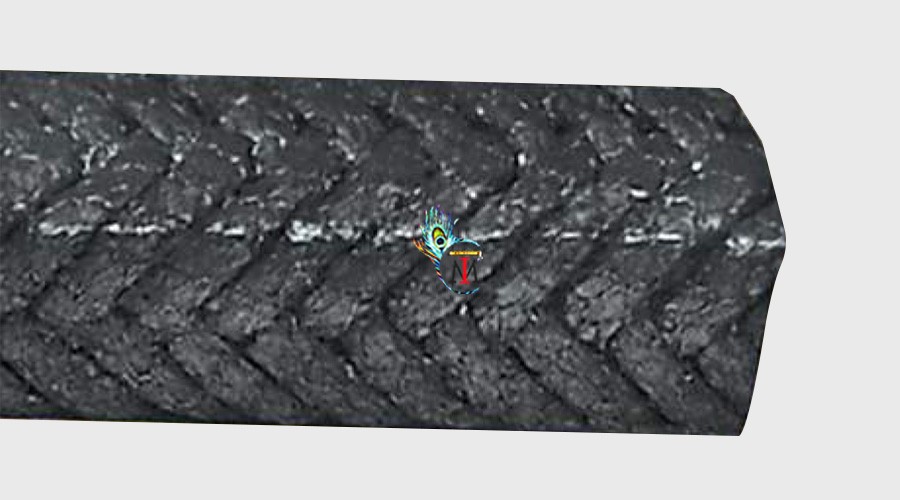

Fire Safe Packing (MI-3912)

By Fluid Sealing Asbestos & Non Asbestos Gland Packing

MI-3912 is an Expanded High Purity Graphite Packing (high carbon content) having an Inconnel Wire Mesh jacketing over each yarn, further reinforced with multiple Inconnel wire inside each yarn. This packing exhibits extreme pressure and extrusion resistance properties. the packing exterior is densely impregnated with custom made lubricating agents to reduce stem friction and a corrosion inhibitor (passive) to prevent galvanic corrosion of stems. This packing can withstand extreme temperature, mechanical stress and cyclic loads owing to its construction.