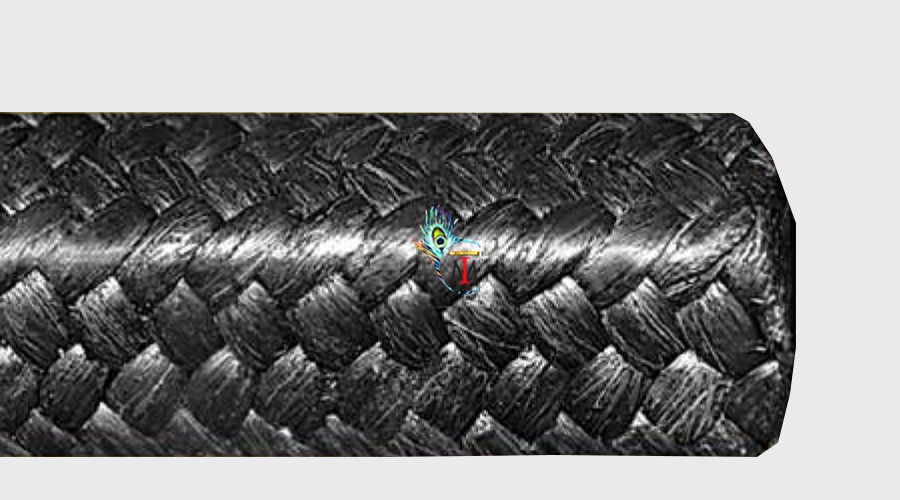

PTFE Graphite Packing with Synthetic Fiber Reinforcement (MI-3501)

By Fluid Sealing Asbestos & Non Asbestos Gland Packing

MI-3501 is a unique “low compression” braided Non Asbestos Gland Packing manufactured from PTFE Graphite Yarn reinforcedwith high tensile strength Synthetic Fiber. The PTFE Graphite Yarn used in constructing the packing is intimately bonded with Graphite for better heat dissipation and cooler shaft runs. Each Yarn of PTFE Graphite is then reinforced with a Synthetic Fiber to increase the longevity of the packing by providing strength to it. It is seen that when the gland follower is used time and again to tight and adjust the packing rings to stop leakage, the packing rings get compressed and leads to a void in the stuffing box. This void is either filled by inserting more rings or replacing all the old rings with new ones leading to increase in maintenance cost. But the use of this low compression packing helps to do away with this and reduces the maintenance cost in long run.